Recently, The Department of Economy and Informatization of

Zhejiang Province released the List of 5G Fully Connected Factories in Zhejiang

Province by 2024 Shanghai Universal Ningbo Container Factory, a

subsidiary of COSCO SHIPPING Development Successfully awarded as “5G Fully Connected

Factory in Zhejiang Province” Leading a new era of efficient and sustainable industry What is a 5G fully connected factory? Through the 5G network's high speed, low latency and

high reliability Production data can be transmitted in real-time and

analyzed accurately Realized digitalized control and efficient

collaborative operation of the whole process Forming an intelligent manufacturing layout covering

multiple application scenarios such as collaborative design, production scheduling,

intelligent warehouse operation management, etc. In recent years Ningbo Container Factory continues to explore Based on 5G, big data, artificial intelligence and

other cutting-edge technologies Deepen the integration and innovation of “5G+Industrial

Internet”. Promote the “5G+” new

model deeply expand to all areas and links of the container

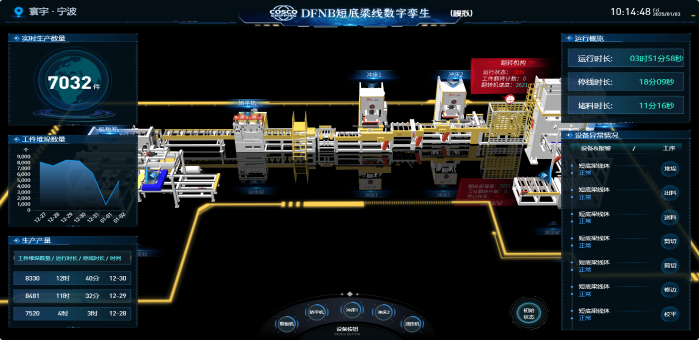

production Okay Now, it's show time for the 5G fully-connected factory. Let the music play and the lights come on. Virtual Reality - Digital Twin

Factory Virtual Reality - Digital Twin Factory Based on 5G technology and 3D modeling applications Virtual reconstruction of key elements in the factory Creates a digital twin model that is exactly the same

scale as the real factory Comprehensive simulation of the production and

operation status of the workshop Rapidly respond to on-site demands to improve

production continuity and stability

AI Eye - Intelligent Security

Controls Combine AI visual recognition with security management Deploying intelligent cameras and setting up security

electronic fences in key areas. Leveraging the high-speed characteristics of 5G

technology Realize automatic monitoring and identification and

real-time alarm Realize all-round intelligent monitoring and management

of the production site Provide a guarantee for safe production management

Cost Reduction and Efficiency -

Energy Management System Build EMS (Energy Management System) based on 5G

technology Installing of intelligent water and electricity meters,

flow meters, sensors cooperating with 5G gateway Real-time monitoring and statistics on production

energy consumption Present production line energy consumption trends and

statistical analysis through charts and graphs. Provide data basis for energy efficiency optimization

and cost saving in production process Enhance the level of energy refinement and

visualization management

Perfect cooperation - human-machine

cooperative work Introduction of industrial robots, high-end machine

tools, flexible automated lines and other intelligent equipment Mechanical arm rotates and swings, welding sparks fly. Utilizing 5G technology to realize intelligent and

controllable product processing and accurate traceability. Effectively reduce the labor intensity of personnel,

reduce the risk factor of operation Man-machine cooperation is well organized, improving

production efficiency and quality

Efficient Operation - Intelligent

Warehousing and Distribution RCS (Remote Control System) based on 5G technology and

AGV Integration with WMS and MES systems Automated warehousing and identification picking out by

AGV Realize the comprehensive digitalization and

intelligentization upgrade of warehousing and distribution

The company will continue to dig deep

into the field of intelligent manufacturing Promote the construction of new

infrastructures such as 5G and industrial Internet Promote the effective integration of

new-generation information technology with the company's business scenarios helping innovation results to take root Better enable the digital transformation

of industries Promote the development of high-quality

and sustainable smart manufacturing |