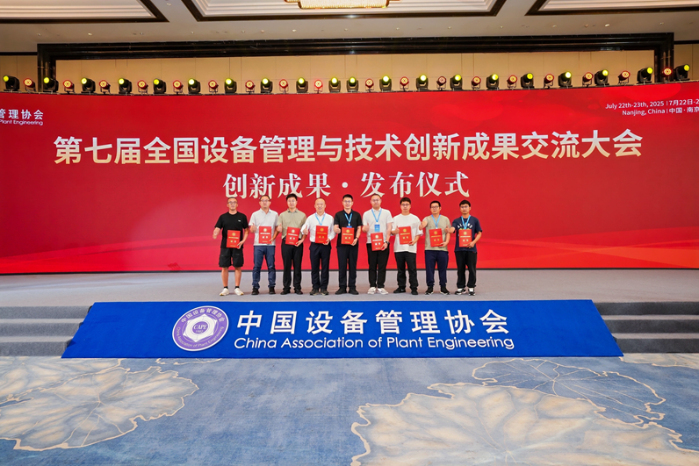

The 7th National

Conference on Equipment Management and Technology Innovation, hosted by the

China Association of Plant Engineering, was recently held in Nanjing.

Centered on the theme "Innovation-driven Development, Intelligence-led

Future," the event featured extensive discussions and announced the

award-winning projects. Several innovations from Shanghai Universal Logistics

Equipment Co., Ltd. ("Shanghai Universal"), a subsidiary of COSCO

SHIPPING Development, and its container factories received honors. First Prize Ningbo Container Factory

– “Application of a Digitalized and Intelligent Smart Manufacturing

System for Containers” By deeply integrating

cutting-edge information technologies such as artificial intelligence, big

data, and 5G with intelligent-manufacturing techniques, and by deploying

advanced CNC machines, industrial robots, AGVs, and other smart-manufacturing

equipment, the project has achieved a remarkable boost in production

efficiency. Second Prize Shanghai Universal –“An

Efficient Training Model for Equipment Talent Based on Deep

Industry-University-Research Integration” By leveraging actual

production equipment and real workplace environments, the program creates

training settings that closely mirror real-world conditions. It delivers

instruction in equipment theory and skills, robotics technology, and

practical applications, achieving effective integration of educational,

technical, and human resources. Jinzhou Container Factory

–“Container Parts Smart Manufacturing Line Based on Multi-machine

Collaborative Technology” By building an integrated

composite line that interconnects all key technical equipment, we have

achieved one-piece-flow intelligent production for container parts—from sheet

loading and processing through finished-part stacking—raising productivity

while lowering operator fatigue. Qidong Container Factory

–“All-scenario Intelligent Integration & Installation of Battery

Modules for Energy-storage Containers” Leveraging vision

recognition and flexible-control technologies, we are driving the

energy-storage container sector toward full automation and intelligence,

delivering multi-dimensional innovation on the production line, boosting

product quality stability, and sharpening our competitive edge. Guangzhou Container

Factory –“Application of a Smart Production Line in the Container Industry” Through the deployment of

a smart production line, we have strengthened safety management, optimized

the handling of material storage and conveyance, and improved cold-workshop

equipment maintenance—raising overall operational efficiency. Lianyungang Container

Factory –“High-efficiency Lock-rod Smart Manufacturing Line” Having passed the China

Classification Society (CCS) factory certification, this lock-rod line

confirms that our products meet the stringent quality standards of the marine

industry and sets a new benchmark for innovation and upgrading. Qingdao Container Factory

–“Research and Promotion of Key Technologies for an Intelligent

Feeding Line for Container T-Floors” With vision inspection

technology and an optimized mechanical structure, the line enables automatic

gripper positioning, material sorting, and flipping. Intelligent line

optimization boosts throughput while reducing labor intensity.

Confronted with the

sweeping changes of the big-data era, the company is fully committed to the

"digital, networked, intelligent" transformation and to living out

the principle of "empowerment through intelligence, driven by

data." We regard technological innovation as the core engine propelling

our high-quality development. As

equipment becomes ever more digitized, our container factories are pressing

ahead with intelligent retrofits and technological breakthroughs, advancing

whole-life-cycle equipment management while driving standardization,

normalization, and unification of equipment governance. These efforts have

markedly boosted production efficiency and service quality, steadily moving

us toward the goal of world-class, benchmark-setting smart factories and

injecting fresh momentum into the innovation-driven growth of the

container-manufacturing industry. The 7th National

Equipment Management & Technology Innovation Awards focus on

whole-life-cycle equipment management. The event showcases the groundbreaking

advances China has achieved in recent years in equipment management,

technological innovation, and industrial upgrading. After rigorous selection,

a portfolio of benchmark technical achievements—rich in demonstrative value

and replicable experience—has emerged, offering invaluable guidance for the

innovative development of key sectors such as equipment R&D and smart

manufacturing. |